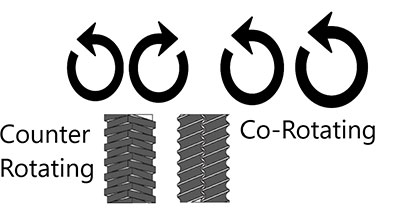

Twin Screw Extruders can generally be classified into two groups:

Co-Rotating Extruders

Co-Rotating machines indicated that the screws turn in the same direction. Often these intermeshing screws turn at higher rpms then counter rotating machines. The material moves over one screw to the other and passes underneath. This flow provides consistent shear and dispersion. These machines are often used in compounding and mixing applications. The screw elements are modular and can be changed relatively easy to give a desired effect inside the barrel segments.

Co-Rotating twin screw extruders have a lot of customization ability due to their modular nature. Many of these machines seen in the market can have multiple venting ports, screw fed material feed sections, and liquid additive sections along the barrel. The customization continues up stream as well. Because the machines are starve fed most extruders will have extensive feed systems with gravimetric or volumetric blending systems up stream.

Things to look for:

- Barrel Length/ Number of segments

- Screw RPM

- Hp Rating of the gearbox

- Torque rating of the screws

Co-Rotating Twin Screw Extruder Brands: Coperion, Berstorff, Leistriz, Werner & Pfleiderer

Counter Rotating Extruders

Counter-Rotating twin screw extruders have two screws that spin in the opposite direction. Also often intermeshing this style of machine is usually found in the profile, pvc or wood composite industry.

These machines typically have a much lower screw rpm and generally have much smaller l/d ratios. The screw direction allows for less shear than a single or co rotating machine.

The two styles of machines within the counter-rotating extruder category known as parallel twin screw extruder and conical twin screw extruder. A parallel twin screw has a consistent barrel diameter through the entire barrel. A conical twin screw extruder has a taper. The feed section is much larger than the end of the barrel. Both counter rotating machines with often have barrel venting. The barrels and screws of these machines are not modular so they may need to be changed for your specific application. Air and water cooling are both common.

Things to look for:

- Hp

- Motor Style AC/DC

- Barrel Length

Counter Rotating Twin Screw Extruder Brands: Milacron, Battenfield-Cincinnati, Krauss Maffei

Tips for Selling a Twin Screw Extruder:

Because of the cost of the screws and barrels on the twin screw machine it is important to know the geometry, metallurgy and condition. Having the barrels measured and having the screw drawings or s/ns is important to help get top dollar for your used extruder.

.JPG)

.JPG)

.JPG)

.JPG)

4444.jpg)

.jpg)

.JPG)

___(2).JPG)

.JPG)

___Co-Rotating___Twin___Screw___Extruder,___New___In___2019___(5).jpg)